Export Office: 21Floor, No.5 Nanhai Zhi Road,Qingdao, Shandong ,China

Work Shop: Beian Industrial zone, Qingdao,Shandong,China

+86 532 88256399

Martin Li

Inquiry now

Size: 1/8"-4" threaded and socket weld type

Pressure:

Socket weled : 3000LB 6000LB 9000LB (sch80 sch160 xxs)

Threaded : 2000LB 3000LB 6000LBS (sch80 sch160 xxs)

Conection: Thread (NPT, BSP,RP, G) ,Socket Welding

Type: Elbow, Tee, nipple, full coupling, half coupling, lateral, cross,cap, plug, hex head nipple, swage nipple, union, weldolet, sockolet, threadolet, nipolet, elbolet, latrolet etc.

Standard: ANSI B16.11,EN10241, BS3799,JIS B2316,MSS SP-83,MSS SP-79;

Material: Stainless steel, Carbon steel and Duplex stainless steel

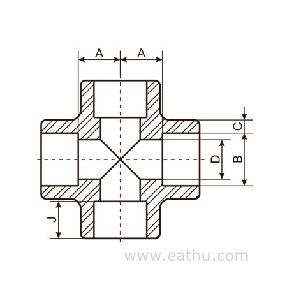

Socket Weld Cross:A cross pipe fitting is used to join 4 pipes or branch the pipes to 4 way.Put each pipes into each socket weld bores of socket weld cross,and welding them together to form a cross pipe line.

Socket Weld Cross Dimension

| DN | Nom. | Center to Bottom of Socket-A | Socket | Bore Dia.Of Fitting | Socket Wall Thickness(2) | Body Wall Thickness | Depth | ||||||||||||||

| Pipe | Bore | D | C | G | of | ||||||||||||||||

| Size | 90°Elbows | 45°Elbows | Dia. | Class Designation | Class Designation | Socket | |||||||||||||||

| Tees,Crosses | B | Min. | |||||||||||||||||||

| Class Designation | Class Designation | Class Designation | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | J | ||||||||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | Ave. | Min. | Ave. | Min. | Ave. | Min. | Min. | Min. | Min. | ||||

| 6 | 1/8" | 11 | 11 | --- | 8 | 8 | --- | 10.8 | 6.9 | 4 | --- | 3.18 | 3.18 | 3.96 | 3.43 | --- | --- | 2.41 | 3.15 | --- | 9.5 |

| 8 | 1/4" | 11 | 13.5 | --- | 8 | 8 | --- | 14.2 | 9.3 | 6.4 | --- | 3.78 | 3.3 | 4.6 | 4.01 | --- | --- | 3.02 | 3.68 | --- | 9.5 |

| 10 | 3/8" | 13.5 | 15.5 | --- | 8 | 11 | --- | 17.6 | 12.6 | 9.2 | --- | 4.01 | 3.5 | 5.03 | 4.37 | --- | --- | 3.2 | 4.01 | --- | 9.5 |

| 15 | 1/2" | 15.5 | 19 | 25.5 | 11 | 12.5 | 15.5 | 21.8 | 15.8 | 11.8 | 6.4 | 4.67 | 4.09 | 5.97 | 5.18 | 9.35 | 8.18 | 3.73 | 4.78 | 7.47 | 9.5 |

| 20 | 3/4" | 19 | 22.5 | 28.5 | 13 | 14 | 19 | 27.2 | 21 | 15.6 | 11.1 | 4.9 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 | 3.91 | 5.56 | 7.82 | 12.5 |

| 25 | 1" | 22.5 | 27 | 32 | 14 | 17.5 | 20.5 | 33.9 | 26.7 | 20.7 | 15.2 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 | 4.55 | 6.35 | 9.09 | 12.5 |

| 32 | 1-1/4" | 27 | 32 | 35 | 17.5 | 20.5 | 22.5 | 42.7 | 35.1 | 29.5 | 22.8 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 | 4.85 | 6.35 | 9.7 | 12.5 |

| 40 | 1-1/2" | 32 | 38 | 38 | 20.5 | 25.5 | 25.5 | 48.8 | 40.9 | 34 | 28 | 6.35 | 5.54 | 8.92 | 7.8 | 12.7 | 11.12 | 5.08 | 7.14 | 10.15 | 12.5 |

| 50 | 2" | 38 | 41 | 54 | 25.5 | 28.5 | 28.5 | 61.2 | 52.5 | 42.9 | 38.2 | 6.93 | 6.04 | 10.92 | 9.5 | 13.84 | 12.12 | 5.54 | 8.74 | 11.07 | 16 |

| 65 | 2-1/2" | 41 | --- | --- | 28.5 | --- | --- | 73.9 | 62.7 | --- | --- | 8.76 | 7.67 | --- | --- | --- | --- | 7.01 | --- | --- | 16 |

| 80 | 3" | 57 | --- | --- | 32 | --- | --- | 89.8 | 78 | --- | --- | 9.52 | 8.3 | --- | --- | --- | --- | 7.62 | --- | --- | 16 |

| 100 | 4" | 66.5 | --- | --- | 41 | --- | --- | 115.2 | 102.3 | --- | --- | 10.69 | 9.35 | --- | --- | --- | --- | 8.56 | --- | --- | 16 |

(1) Dimensions in Millimeters.

(2) Average of socket wall thickness around periphery shall be no less than listed values. The minimum values are permitted in localized areas.

(3) Upper and lower values for each size are the respective maximum and minimum dimensions.

Export Office: 21Floor, No.5 Nanhai Zhi Road,Qingdao, Shandong ,China

Work Shop: Beian Industrial zone, Qingdao,Shandong,China

+86 532 88256399

Martin Li

© 2020 Qingdao Fluido Industrial Co.,Ltd. All Rights Reserved.