Export Office: 21Floor, No.5 Nanhai Zhi Road,Qingdao, Shandong ,China

Work Shop: Beian Industrial zone, Qingdao,Shandong,China

+86 532 88550859

Joe

Inquiry now

Size: 1/8"-6" Lug Nut Union

Standard: ANSI B16.11

Material: Stainless steel or Carbon steel

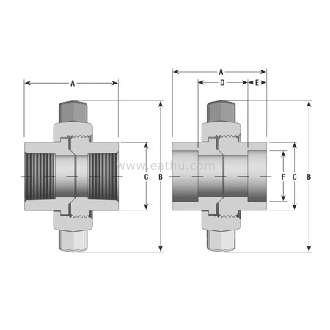

Lug Nut Union Dimension

CLASS 3000

| PIPE SIZE | 3/8" | 1/2" | 3/4" | 1" | 1-1/4" | 1-1/2" | 2" | 2-1/2" | 3" | 4" |

| A | 1.875 | 1.984 | 2.297 | 2.891 | 2.906 | 3.031 | 3.484 | 4.063 | 4.484 | 8.031 |

| B | 2.563 | 3 | 3.625 | 4.25 | 5 | 5.625 | 6.375 | 7.188 | 8 | 10.359 |

| C | 1.031 | 1.031 | 1.484 | 1.813 | 2.188 | 2.469 | 3.031 | 3.656 | 4.406 | 5.453 |

| D | 1.125 | 1.125 | 1.297 | 1.891 | 1.904 | 2.031 | 2.234 | 2.813 | 3.234 | 6.531 |

| Emin | 0.375 | 0.375 | 0.5 | 0.5 | 0.5 | 0.5 | 0.625 | 0.625 | 0.625 | 0.75 |

| F | 0.69 | 0.855 | 1.065 | 1.33 | 1.675 | 1.915 | 2.406 | 2.906 | 3.535 | 4.545 |

| Weight(LBS) | 0.59 | 0.91 | 3.12 | 2.28 | 3.48 | 4.66 | 7.07 | 11.4 | 15.42 | --- |

CLASS 6000

| PIPE SIZE | 3/8" | 1/2" | 3/4" | 1" | 1-1/4" | 1-1/2" | 2" | 2-1/2" | 3" | 4" |

| A | --- | 2.375 | 2.578 | 2.89 | 3.125 | 3.578 | 4.141 | --- | --- | --- |

| B | --- | 3.625 | 4.25 | 5 | 5.625 | 6.375 | 7.188 | --- | --- | --- |

| C | --- | 1.469 | 1.797 | 2.172 | 2.563 | 3.031 | 3.688 | --- | --- | --- |

| D | --- | 1.625 | 1.578 | 1.89 | 2.125 | 2.578 | 2.89 | --- | --- | --- |

| E | --- | 0.375 | 0.5 | 0.5 | 0.5 | 0.5 | 0.625 | --- | --- | --- |

| F | --- | 0.855 | 1.065 | 1.33 | 1.675 | 1.915 | 2.406 | --- | --- | |

| Weight(LBS) | --- | 1.95 | 2.84 | 3.96 | --- | 7 | 14.16 | --- | --- | --- |

Note:

1. Seating characteristics of MSS SP-83 Unions.

2. The "B" dimension is the diameter across the lugs of union nut.

3.Twin Lug design offered in sizes up to 3/4" Class 3000 & 1/2" Class 6000.

4. Tri-Lug design offered in sizes from 1" to Class 3000&3/4" to 2" Class 6000.

5. Quad-lug design offered in 4" Class 3000.

Export Office: 21Floor, No.5 Nanhai Zhi Road,Qingdao, Shandong ,China

Work Shop: Beian Industrial zone, Qingdao,Shandong,China

+86 532 88550859

Joe

© 2020 Qingdao Fluido Industrial Co.,Ltd. All Rights Reserved. Qingdao fluido valve