Export Office: 21Floor, No.5 Nanhai Zhi Road,Qingdao, Shandong ,China

Work Shop: Beian Industrial zone, Qingdao,Shandong,China

+86 532 88550859

Joe

Inquiry now

Size: 1/2"-80"/DN15-DN2000

Material: Carbon Steel, Stainless Steel, Alloy Steel

Standard: ASME/ANSI B16.9, B16.11, B16.28, JIS B2311, B2312, B2312, B2316 ASTM A403 MSS SP-43, SP-83, SP-97

Type: Seam Or Seamless

End: beveled end

Surface: Black Paint/Rust-proof Oil/Hot Dipped Galvanized

Wall Thickness: SCH10/10S, SCH20/20S, STD, SCH40/40S, XS, SCH80,SCH100, SCH120, SCH140, SCH160, XXS etc.(for ANSI),SGP(for JIS)

Elbow Angles: 30/45/60/90/180°

Connection: Welding

Butt weld long radius 90° Reducing Elbow LR is a kind of butt weld fittings. The 90-degree reducing elbow is also called the 90-degree reducing elbow, which is used to connect two steel pipes of different sizes for steering. The usual production process is to cut a 90-degree elbow blank with a standard pipe diameter, and then deform it in the mold with a hydraulic press, so that the two ends of the elbow have different sizes. After hydroforming, a shaping machine is used for shaping. 90-degree reducing elbow processing is a metal cold deformation processing method, it is one of the main methods of metal plastic processing (or pressure processing), and also belongs to the material forming engineering technology.

The advantages of the 90-degree reducing elbow manufacturing process are mainly manifested in the following aspects:

1. Need to use elbow blank as raw material, no need to reopen the mold, saving mold cost and time, and at the same time, it can accept small batch orders from customers.

2. The blank of the reducing elbow is the elbow blank, so the workmanship is simple, the accuracy is easy to ensure, and the assembly and welding are convenient.

3. Due to the above two reasons, the manufacturing cycle can be shortened, and the cost of producing reducing elbows is greatly reduced.

As a high-quality pipe flange exporter in northern China, Fluido has a good price and quality in 90-degree reducing elbow products, and can produce 90-degree reducing elbows based on a small amount of project need. The quality and price of 90-degree reducing elbows are advantageous, please contact Fluido sales department to get the price list.

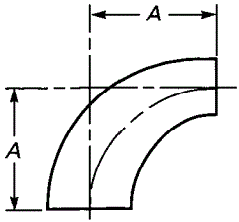

ASME B16.9: Reducing Elbow 90D L/R

Dimensions of 90D Long Radius Reducing Elbow BW(ASME B16.9)

| NPS | Outside Diameter | Center to End | NPS | Outside Diameter | Center to End | ||

| Large end | Small end | A | Large end | Small end | A | ||

| 2×1 1/2 | 60.3 | 48.3 | 76 | 10×8 | 273.0 | 219.1 | 381 |

| 2×1 1/4 | 60.3 | 42.2 | 76 | 10×6 | 273.0 | 168.3 | 381 |

| 2×1 | 60.3 | 33.4 | 76 | 10×5 | 273.0 | 141.3 | 381 |

| 2 1/2×2 | 73.0 | 60.3 | 95 | 12×10 | 323.8 | 273 | 457 |

| 2 1/2×1 1/2 | 73.0 | 48.3 | 95 | 12×8 | 323.8 | 219.1 | 457 |

| 2 1/2×1 1/4 | 73.0 | 42.2 | 95 | 12×6 | 323.8 | 168.3 | 457 |

| 3×2 1/2 | 88.9 | 73.0 | 114 | 14×12 | 355.6 | 323.8 | 533 |

| 3×2 | 88.9 | 60.3 | 114 | 14×10 | 355.6 | 273 | 533 |

| 3×1 1/2 | 88.9 | 48.3 | 114 | 14×8 | 355.6 | 219.1 | 533 |

| 3 1/2×3 | 101.6 | 88.9 | 133 | 16×14 | 406.4 | 355.6 | 610 |

| 3 1/2×2 1/2 | 101.6 | 73.0 | 133 | 16×12 | 406.4 | 323.8 | 610 |

| 3 1/2×2 | 101.6 | 60.3 | 133 | 16×10 | 406.4 | 273 | 610 |

| 4×3 1/2 | 114.3 | 101.6 | 152 | 18×16 | 457 | 406.4 | 686 |

| 4×3 | 114.3 | 88.9 | 152 | 18×14 | 457 | 355.6 | 686 |

| 4×2 1/2 | 114.3 | 73.0 | 152 | 18×12 | 457 | 323.8 | 686 |

| 4×2 | 114.3 | 60.3 | 152 | 18×10 | 457 | 273 | 686 |

| 5×4 | 141.3 | 114.3 | 190 | 20×18 | 508 | 457 | 762 |

| 5×3 1/2 | 141.3 | 101.6 | 190 | 20×16 | 508 | 406.4 | 762 |

| 5×3 | 141.3 | 88.9 | 190 | 20×14 | 508 | 355.6 | 762 |

| 5×2 1/2 | 141.3 | 73.0 | 190 | 20×12 | 508 | 323.8 | 762 |

| 6×5 | 168.3 | 141.3 | 229 | 20×10 | 508 | 273 | 762 |

| 6×4 | 168.3 | 114.3 | 229 | 24×22 | 610 | 559 | 914 |

| 6×3 1/2 | 168.3 | 101.6 | 229 | 24×20 | 610 | 508 | 914 |

| 6×3 | 168.3 | 88.9 | 229 | 24×18 | 610 | 457 | 914 |

| 8×6 | 219.1 | 168.3 | 305 | 24×16 | 610 | 406.4 | 914 |

| 8×5 | 219.1 | 141.3 | 305 | 24×14 | 610 | 355.6 | 914 |

| 8×4 | 219.1 | 114.3 | 305 | 24×12 | 610 | 323.8 | 914 |

*All dimensions are in mm unit(inch unit data sheet is also available upon request).

*Check the tolerances and materials for butt welding pipe fittings from "Price List and Techinical"

*Tolerances of dimensions are in conformance with ASME B16.9

Butt welding pipe fittings standard:

ASME B16.49-2007 Factory-Made,Wrought Steel, Buttwelding Induction Bends for Transportation and

ASME-B16.9-2007 Factory-Made Wrought Butt Welding Fitting

DIN2617-1991 Steel butt-welding pipe fittings

JIS G3452 SGP 1997 Steel Butt-welding pipe fittings for ordinary use

Weight for butt welding pipe fitting

Tolerances for ASME DIN JIS MSS Butt Welding Pipe Fittings

Export Office: 21Floor, No.5 Nanhai Zhi Road,Qingdao, Shandong ,China

Work Shop: Beian Industrial zone, Qingdao,Shandong,China

+86 532 88550859

Joe

© 2020 Qingdao Fluido Industrial Co.,Ltd. All Rights Reserved. Qingdao fluido valve