Export Office: 21Floor, No.5 Nanhai Zhi Road,Qingdao, Shandong ,China

Work Shop: Beian Industrial zone, Qingdao,Shandong,China

+86 532 88550858

Martin

Inquiry now

Size: 1/8"-4" socket weld type

Pressure:

Socket weled : 3000LB 6000LB 9000LB (sch80 sch160 xxs)

Connection: Socket Welding

Standard: ANSI B16.11,EN10241, BS3799,JIS B2316,MSS SP-83,MSS SP-79;

Material: Stainless steel, Carbon steel and Duplex stainless steel

Socket Weld Lateral:In pipeline system, the lateral is to change the direction of the pipeline. According to the view points, there are 45 degree, 90 degree two most commonly used types, according to the requirements of the project ,also includes 60 degree and other abnormal Angle lateral. Socket weld lateral, mainly manufactured by round steel or steel ingot .Heat the steel ingot, put them in mold cavities,then forging to blanks by forging machine, and then after the lathe machining forming a high pressure lateral pipe fitting.

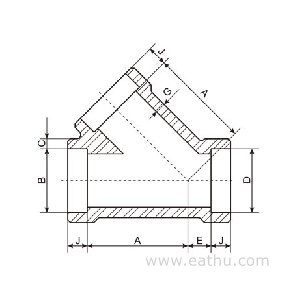

Socket Weld Lateral Dimension

3000LB

| DN | Nom.Pipe | B² | B² | D² | A | E | G² | J² | |

| Size | (Avg.) | (Min.) | (Min.) | (Min.) | |||||

| 15 | 1/2" | 21.8 | 4.67 | 4.09 | 15.8 | 35 | 9 | 3.75 | 9.5 |

| 20 | 3/4" | 27.2 | 4.9 | 4.27 | 21 | 41 | 9 | 3.95 | 12.5 |

| 25 | 1" | 33.9 | 5.69 | 4.98 | 26.7 | 51 | 12 | 4.55 | 12.5 |

| 32 | 1-1/4" | 42.7 | 6.07 | 5.28 | 35.1 | 59 | 17 | 4.85 | 12.5 |

| 40 | 1-1/2" | 48.8 | 6.35 | 5.54 | 40.9 | 68 | 21 | 5.1 | 12.5 |

| 50 | 2" | 61.2 | 6.93 | 6.04 | 52.5 | 95 | 24 | 5.55 | 16 |

| 65 | 2-1/2" | 73.9 | 8.76 | 7.67 | 62.7 | 118 | 38 | 7.05 | 16 |

6000LB

| DN | Nom.Pipe | B² | B² | D² | A | E | G² | J² | |

| Size | (Avg.) | (Min.) | (Min.) | (Min.) | |||||

| 15 | 1/2" | 21.8 | 5.97 | 5.18 | 11.8 | 41 | 9 | 4.78 | 9.5 |

| 20 | 3/4" | 27.2 | 6.96 | 6.04 | 15.6 | 51 | 12 | 5.56 | 12.5 |

| 25 | 1" | 33.9 | 7.92 | 6.93 | 20.7 | 59 | 17 | 6.35 | 12.5 |

| 32 | 1-1/4" | 42.7 | 7.92 | 6.93 | 29.5 | 68 | 21 | 6.35 | 12.5 |

| 40 | 1-1/2" | 48.8 | 8.92 | 7.8 | 34 | 95 | 24 | 7.14 | 12.5 |

| 50 | 2" | 61.2 | 10.92 | 9.5 | 42.9 | 106 | 31 | 8.74 | 16 |

(1) Dimensions in Millimeters.

(2) Average of socket wall thickness around periphery shall be no less than listed values. The minimum values are permitted in localized areas.

(3) Upper and lower values for each size are the respective maximum and minimum dimensions.

Export Office: 21Floor, No.5 Nanhai Zhi Road,Qingdao, Shandong ,China

Work Shop: Beian Industrial zone, Qingdao,Shandong,China

+86 532 88550858

Martin

© 2020 Qingdao Fluido Industrial Co.,Ltd. All Rights Reserved. Qingdao fluido valve