Export Office: 21Floor, No.5 Nanhai Zhi Road,Qingdao, Shandong ,China

Work Shop: Beian Industrial zone, Qingdao,Shandong,China

+86 532 88550859

Joe

Flange

Slip On Flange

View MoreFlat Flange

View MoreWeld Neck Flange

View MoreBlind Flange

View MoreThreaded Flange

View MoreLapped Joint Flange

View MoreSocket Weld Flange

View MoreBacking Rings(Flanges) For HDPE Pipe

View MoreSpectacle Blind Flange

View MoreOrifice Flange

View MoreLong Weld Neck Flange

View MoreBolt/Nut for flanges

View MoreGet A Free Quote

Forged Flange Manufacturers in China

Pipe flanges are basically plates or ring, used to connect pipes, valve and other pipe equipment to form a piping system. Flanges are predesigned to meet process conditions. Standards exist that provide standardised dimensions and material types.

Eathu is a professional steel pipe flanges manufacturer of china, we can produce flange with various standards like ANSI/ BS EN1092 / DIN / AWWA / JIS / UNI / GOST/ S.A.B.S / AS or according to the drawing or samples.

Pipe Flanges Raw Material Specifications:

·Stainless Steel Flange : ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L

·Duplex & Super Duplex Steel Flange : ASTM A182 / ASME SA182 F44, F 45, F51, F 53, F 55, F 60, F 61

·Carbon Steel Flange : ASTM A105 / ASME SA105 ASTM / ASME A 350 , ASTM A181 LF2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F706

·Low Temperature Carbon Steel Flange: ASTM A350, LF2, LF3

·Alloy Steel Flange : ASTM A182 / ASME SA182 & A387 F1, F5, F9, F11, F12, F22, F91

·Copper Alloy Steel Flange : ASTM SB 61 , SB62 , SB151 , SB152 UNS No. C 70600 (Cu-Ni 90/10), C 71500 (Cu-Ni 70/30), UNS No. C 10100, 10200, 10300, 10800, 12000, 12200

·Nickel Alloy Flange : ASTM SB564, SB160, SB472, SB162 Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020)

The standard for flanges:

ASME/ANSI FLANGE

ASME/ANSI B16.5 FLANGE

ASME B16.5 and ANSI B16.5 Pipe Flanges and Flanged Fittings: NPS 1/2 through NPS 24 Metric/Inch Standard covers pressure-temperature ratings, materials, dimensions, tolerances, marking, testing, and methods of designating openings for pipe flanges and flanged fittings.

ASME/ANSI B16.5 LONG NECK WELD FLANGE

A long neck welding flange is similar to a standard weld neck flange, but the neck is considerably longer. This type is often used as a nozzle for a barrel or column. In addition, there are the type LWN Heavy Barrel (HB) and the Equal LWN Barrel (E); they have a different shape and a thicker wall.

ASME/ANSI B16.47 FLANGE A(MSS SP44)SERIES,B(API605)SERIES

ASME B16.5 and ANSI B16.5 only cover sizes up to 24 inches. For bigger sizes, ASME B16.47 standard covers pipe flanges in sizes 26” through 60” and in pressure class ratings 75, 150, 300, 400, 600, and 900. ASME B16.47 Series A flange was known as MSS SP44, ASME B16.47 Series B flange was also formerly known as API 605 flange.

ASME/ANSI B16.48 LINE BLANKS FLANGE

ASME B16.48 Spectacle Flange/Spectacle Blind/Paddle Flange/Spades

A spectacle blind is a safety device used to isolate a section of line or piece of equipment when the line or equipment needs to be inspected or removed from service. It is different than a valve in that the blind is a permanent or long term isolation device. A spectacle blind is machined from a single piece of metal that is cut to match the pipe size, fit between two pipe flanges and requires an additional gasket when it is installed. Also, the bolts will need to be lengthened depending on what piping class and size blind is used. The thickness of the spectacle blind is specified based on the line pressure and pipe size.

ASME/ANSI B16.36 ORIFIC FLANGE

ASME B16.36 orifice flange standard covers flanges (similar to those covered in ASME B16.5) that have orifice pressure differential connections. The coverage of ASME B16.36 is limited to the following: (a) Welding Neck Flanges Classes 300-2500 (b) slip-on and threaded Class 300.

API6A/6B FLANGE

The flange standards API 6A and ASME/ANSI B16.5 have the same dimensions - but the API 6A flanges are rated for higher pressures as indicated below:

API vs. ASME/ANSI Flanges with the same Dimensions | ||||

Flange | Pressure Class Rating | Nominal Size Range | ||

ASME/ANSI B16.5 | API 6A | ASME/ANSI B16.5 | API 6A | |

Weld neck | 600 | 2000 | 1/2" - 24" | 1-13/16" - 11" |

900 | 3000 | |||

1500 | 5000 | |||

Blind and Threaded | 600 | 2000 | 1-13/16" - 21-1/4" | |

900 | 3000 | 1-13/16" - 20-3/4" | ||

1500 | 5000 | 1-13/16" - 11" | ||

AWWA C207 Steel Pipe Flanges for Waterworks Service

This standard covers two types of slip-on flanges, ring type and hub type, that may be used interchangeably if the dimensions given in the standard are used. The standard also covers blind flanges. The flange types and the tables that describe them are: Ring-type, slip-on flanges; Hub-type, slip-on flanges; and Blind flanges. Unless otherwise specified by the purchaser, the manufacturer of pipe fittings will select the type to be used. The purpose of this standard is to provide purchasers and manufacturers minimum material requirements and dimensions for a variety of steel flanges for attachment to steel water pipe and fittings.

Both the AWWA and ANSI have thorough standards for flanges, and the two standards are different in several ways. AWWA standards provide flange properties intended for potable water use only. In contrast, ANSI standards are aimed at industrial flange applications. For example, AWWA flange ratings are applicable only at atmospheric temperature, while ANSI ratings cover flange installations from -20°F to 1500°F.

ANSI covers numbered class flanges from 150 to 2500, and AWWA standards encompass lettered flange classes B, E, F, and the commonly used class D connection. AWWA provides ratings for a much broader range of nominal pipe sizes (3″-144″) than ANSI provides (1/2″-24″).

Finally, ANSI and AWWA flange standards differ in the breadth of applications discussed. ANSI includes information for welded auxiliary connections and tapping, while AWWA does not address those installations. Also, the AWWA standard only encompasses ring, hub type, blind flanges, and threaded iron flanges while the ANSI standard includes all flange types.

This discussion on AWWA flange standards and ANSI flange standards is based on information from ANSI/AWWA C115/A21.15-99: “American National Standard for Flanged Ductile-Iron Pipe with Ductile-Iron or Gray-Iron Threaded Flanges”, ANSI/AWWA C207-94: “AWWA Standard for Steel Pipe Flanges for Waterworks Service-Sizes 4 In. Through 144 In.”, and ANSI B16.5-1981: “Pipe Flanges and Flanged Fittings”.

For drawing, weight and specification please check Backing Rings Flanges For HDPE Pipe

·EN 1092-1 FLANGE

EN 1092 consists of the following four parts:

Part 1: Steel flanges; Part 2: Cast iron flanges;

Part 3: Copper alloy flanges; Part 4: Aluminium alloy flanges.

Eathu produce the flanges according to part 1, it call EN 1092-1 steel flange, below is the size.

EN 1092-1 TYPE 01 Plate Flanges

EN 1092-1 TYPE 11 Weld Neck Flanges

EN 1092-1 TYPE 12 Slip-On Flanges

EN 1092-1 TYPE 13 Threaded Flanges

EN 1092-1 TYPE 05 Blind Flanges

·DIN FLANGE

Although DIN standard flanges now have been superseded by EN 1092-1, it is still commonly used in project practice. DIN series flanges cover an extensive range of pressure ratings from 1 bar(PN 1) to 400 bar(PN 400): 1 bar, 2.5 bar, 6 bar, 10 bar, 16 bar, 25 bar, 40 bar, 64 bar, 100 bar, 160 bar, 250 bar, 320 bar, 400 bar. According to SI unit system, 1 bar = 100 kPa = 0.1 MPa = 14.5 psi. Usually, DIN standard flanges are categorized as:

1) Weld neck flanges: DIN 2630(PN 1 & 2.5); DIN 2631(PN 6); DIN 2632(PN 10); DIN 2633(PN 16); DIN 2634(PN 25); DIN 2635(PN 40); DIN 2636(PN 64); DIN 2637(PN 100); DIN 2638(PN 160); DIN 2628(PN 250); DIN 2629(PN 320); DIN 2627(PN 400)

2) Lapped flanges plain collar(lapped joint): DIN 2641(PN 6); DIN 2642(PN 10)

3) Flat flanges for welding(Slip On): DIN 2573(PN 6); DIN 2576(PN 10); DIN 2502(PN 16); DIN 2503(PN 25 & 40)

4) Blind flanges: DIN 2527(PN 6, 10, 16, 25, 40, 64 & 100)

5) Loose flanges and rings for welding(slip on and plain colloar): DIN 2652(PN 6); DIN 2653(PN 10); DIN 2655(PN 25); DIN 2656(PN 40)

6) Loose flanges and ring with neck for welding: DIN 2673(PN 10)

7) Oval plain threaded flanges: DIN 2558(PN 6)

8) Oval flanges with neck threaded: DIN 2561(PN 10 & 16)

9) Long weld neck flanges: DIN 28115(PN 10 & 25)

10) Hubbed slip on flanges for welding: DIN 86029(PN 10); DIN 86030(PN 16)

11) Threaded flanges with neck: DIN 2565(PN 6); DIN 2566(PN 10 & 16); DIN 2567(PN 25 & 40); DIN 2568(PN 64); DIN 2569(PN 100)

·JIS FLANGE

JIS B 2220 Steel pipe flanges

This Standard specifies steel pipe flanges (hereafter referred to as "flanges") of nominal sizes 10 A to 1 500 A for nominal pressures 5 K, 10K, 10K light type, 16K, 20K, 30K, 40K and 63K which are used to join parts for piping, such as steel pipes and valves used for ordinary piping 1), pressure piping 2), high pressure piping 3), high temperature piping 4), alloy steel piping 5) and stainless steel piping 6) for steam, air, gas, water, oil, etc.

This Standard is also applicable to flanges which are integral with the piping part, and constituting a part thereof (hereafter referred to as the "integral flanges").

·JPI FLANGE The Japan Petroleum Institute

JPI-7S-15-11, Pipe Flanges for the Petroleum Industry, 6,000, (4,000). JPI-7S-16-14, Non-Metallic Gaskets Dimension for Petroleum Industry, 3,000, (2,000).

·BS FLANGE

BS 10 FLANGE

BS 4504 FLANGES

BS 86029 FLANGE

BS 86030 FLANGE

BS 3293 FLANGE

·UNI FLANGE

Flat Flange:UNI 2276-67;UNI 2277-67;UNI 2278-67;UNI 6083-67;UNI 6084-67;

Lap Joint Flange, Loose Flange:UNI 6088-67; UNI 6089-67;UNI 6090-67;UNI 2299-67;UNI 2300-67

Weld Neck Flange:UNI 2225-67;UNI 2226-67;UNI 2229-67;UNI 2280-67; UNI 2281-67; UNI 2282-67;UNI 2283-67;UNI 2284-67; UNI 2285-67;UNI 2286-67

Threaded Neck Flange:UNI 2253-67;UNI 2254-67

Blind Flange:UNI 6091-67; UNI 6092-67; UNI 6093-67; UNI 6094-67; UNI 6095-67; UNI 6096-67;UNI 6097-67;UNI 6098-67;UNI 6099-67

Weld Neck Flange collar to weld head: UNI 2289-67;UNI 2290-67;UNI 2291-67

·ISO7005 ISO Flanges Standard (ISO 7005-1, ISO 9624)

Pipe flanges -- Part 1: Steel flanges for industrial and general service piping systems.

ISO 7005-1:2011 establishes a base specification for pipe flanges suitable for general purpose and industrial applications including, but not limited to, chemical process industries, electric power generating industries, petroleum and natural gas industries. It places responsibility for the selection of a flange series with the purchaser.

It is applicable to flanges within facilities engaged in the processing or handling of a wide variety of fluids, including steam, pressurized water and chemical, petroleum, natural gas or related products.

ISO 7005-1:2011 is also applicable to packaged equipment piping, which interconnects individual pieces or stages of equipment within a packaged equipment assembly for use within facilities engaged in the processing or handling of a variety of fluids, including steam and chemical, petroleum, natural gas or related products.

·GOST FLANGE

Gost flange is a flange system from Russia, include Plate Flanges (GOST12820-80),Blind Flanges (GOST12836-67),Welding neck Flanges (GOST12821-80), Steel Butt-Welded Flanges GOST12821-80 etc., size from DN15 to DN1600, Plate flange, welding neck flange, slip on welding plate flange.

·S.A.B.S 1123 FLANGE South African pipe flanges standard.

The British Standard SABS or the standard for SANS 1123 Flange, 1962, is a specification that covers Flanges and Bolting for Valves, Pipes, and Fittings. This Sans 1123 T1000 covers boss, plain, integrally cast or forged, and welding neck type flanges, in ten tables.

·AUSTRALIAN STANDARD FLANGE

AS2129 FLANGE: Australian Standard Flanges for pipes, valves andfittings SECTION 1 SCOPE AND GENERAL 1.1 SCOPE

AS4087 FLANGE: LICENCE for AS 4087-2004 Metallic flanges for waterworks purposes Licensee

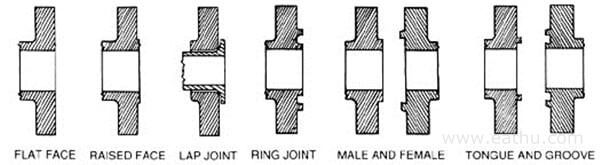

The flange type

Weld Neck (WN), Slip on (SO), Blind (BL), Threaded (THR), Socket Weld (SW), Lap Joint (LJ), Orifice Flanges, RTJ and custom flanges.

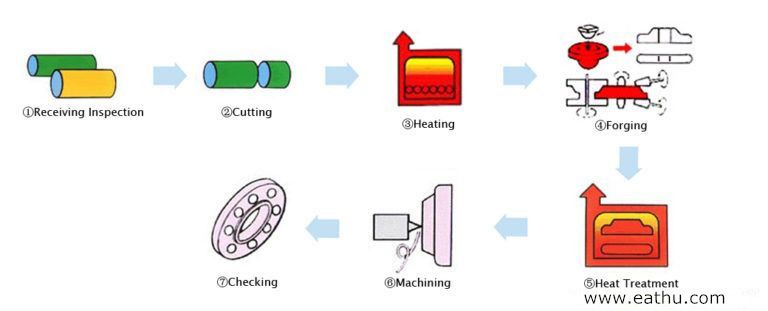

Forged Flange Manufacturing Process

The forging process is usually composed of the following processes, namely, the selection of quality steel billet, heating, forming and cooling.

1. Inspection of Raw Material – The key raw material for producing flanges is steel billets or hot rolled bars. All raw materials purchased are supplied with test reports as per EN 10204 3.1, with full traceability. It is the first compulsory step in the production process for flanges to guarantee good quality. The raw materials are re-tested inhouse for assurance on chemical composition, mechanical capacity and metallographic analysis.

2.Cutting Raw Material – Correctly and strictly controlling cutting size and proportion can ensure adequate control on the cost.

3.Heating – It is a very important step for flange quality. It is the necessary to record the heating temperature in details to avoid overheating. Overheating will destroy the structure of the metal and mechanical properties pf the raw materials.

4.Forging – Forging process is divided into free forging and die forging. The forging time and strength of flange is different for different pressure class.

5.Heat Treatment – The purpose of heat treatment is to eliminate the stress inside of flange so that the density is more evenly. Carefully recording the temperature of heat treatment and cooling time are the keys.

6.Forging Blank Inspection – After the heat treatment process has been carried out, a sample of the lot is chosen to test the chemical composition and mechanical property again to ensure all items are qualified.

7.Machining of Forged Blanks – In the machining process, the inspection is carried out along with the processing, so that to guarantee each part of flange is qualified. Machining is undertaken on CNC and/or lathe machines.

8.Finishing Goods Inspection – Finished products will be checked 100% before delivery to ensure the goods are perfect as per ASME, EN or customer standards.

9.Documentation – The whole production process and quality checks at different levels is documented as per standard operation procedure under ISO compliance. It is the guarantee for good quality.

10.Test Certificate: Since we are a ISO and PED certified manufacturer, we can issue test certificate as per EN 10204 3.1 for all the goods at the time of delivery and inspection.

11.Packing: All forgings and flanges are packed in wooden crates or box or pallets to ensure secure movement of goods.

Plate Cut Flanges Manufacturing Process

The process here is relatively simple, with the key raw material being hot rolled plates. This process is mainly used for producing slip on plate flanges and blind flanges for lower thickness. All plates procured are accompanied with tested certificates as per EN 10204 3.1.

1.Circles are cut from plates.

2.Heat treatment is not involved in this process of manufacturing flanges.

3.Drilling and machining is done on circles to achieve the desired dimensions.

4.Goods are visually inspected and marked with relevant standards.

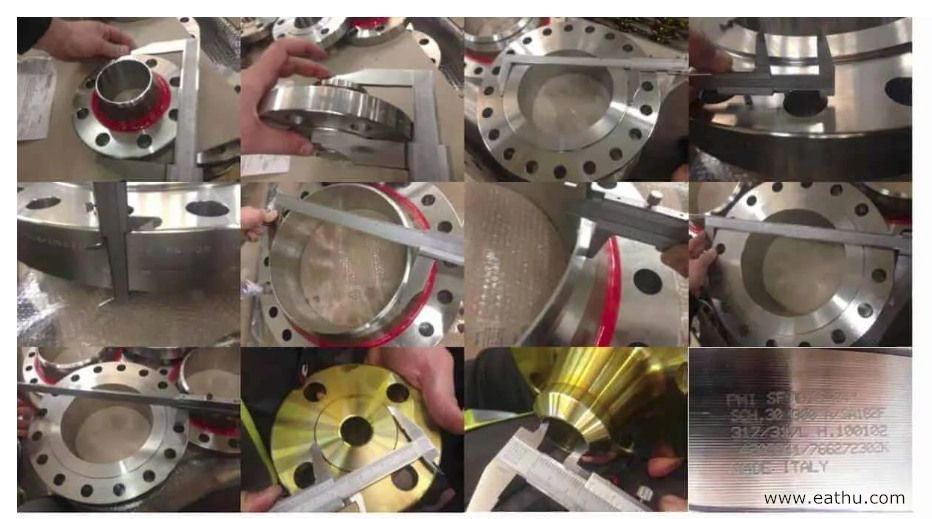

Flanges' inspection:

Following to be confirmed during an inspection of a flange

-Outer & Inner Diameter of body

-Bolt Circle & Bolt hole Diameter

-Hub Diameter & thickness of weld end

-Length of the Hub

-Permissible tolerances are given in B16.5 and B16.47 standards(you can download the tolerances file from Price list and Tech).

Marking

The following shall be marked on flange body

-Manufacturer logo

-ASTM material code

-Material Grade

-Service rating (Pressure-temperature Class))

-Size

-Thickness (Schedule)

-Heat No

-Special marking if any QT (Quenched and tempered) or W (Repair by welding)

Certificate

Eathu Certificate: ISO9001: 2000, TUV PED and AD-2000 certification.

Main Market: United Kingdom, America, Canada, Chile, Peru, Panama, Brazil, Australia, Japan, South Korea, Singapore, Germany and other countries in the world.

Packing: Using Veneer Case or Plywood Case Of Outside, Linoleum And Plastic Cloth Of Inside Dampproof, or other methods according to the requirements of our clients.

Payment term: T/T, L/C or D/P according to Eathu Term

Please contact Eathu sales team if you want more flange information.