Export Office: 21Floor, No.5 Nanhai Zhi Road,Qingdao, Shandong ,China

Work Shop: Beian Industrial zone, Qingdao,Shandong,China

+86 532 88550859

Joe

Inquiry now

Size: 1/8"-4" threaded and socket weld type

Pressure:

Socket weled : 3000LB 6000LB 9000LB (sch80 sch160 xxs)

Threaded : 2000LB 3000LB 6000LBS (sch80 sch160 xxs)

Conection: Thread (NPT, BSP,RP, G) ,Socket Welding

Type: Elbow, Tee, nipple, full coupling, half coupling, lateral, cross,cap, plug, hex head nipple, swage nipple, union, weldolet, sockolet, threadolet, nipolet, elbolet, latrolet etc.

Standard: ANSI B16.11,EN10241, BS3799,JIS B2316,MSS SP-83,MSS SP-79;

Material: Stainless steel, Carbon steel and Duplex stainless steel

A sweep outlet is a type of plumbing fitting used to connect a branch line to the main line in a way that minimizes resistance to flow. Unlike a standard tee fitting, which can create turbulence and restrict flow due to its sharp angles, a sweep outlet features a more gradual curve that allows for a smoother transition.

Key Features of Sweep Outlet Pipe Fittings:

1. Design: The fitting typically has a rounded or curved entry for the branch line, which helps to reduce turbulence and maintain a more efficient flow of liquids or gases.

2. Applications: Commonly used in drainage, venting, and waste systems, sweep outlets are ideal for applications where fluid dynamics are important, such as in plumbing and HVAC systems.

3. Materials: Available in various materials such as PVC, ABS, cast iron, and stainless steel, allowing for use in different environments and with various types of fluids.

4. Sizes: Sweep outlets come in various sizes and diameters to accommodate different pipe sizes and configurations.

5. Installation: They can be connected to pipes using solvent welding, threading, or other methods depending on the material and application.

When selecting a sweep outlet fitting, it’s important to consider the specific requirements of the system, including the type of fluid being transported, the pressure conditions, and local building codes.

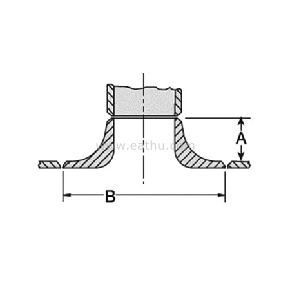

Sweep Outlet Dimension

| Run Size | Outlet Size | Dimensions | |

| Inches | *A | B | |

| 6 to 36 | 1 1/4 | 1 1/4 | 4 |

| 6 to 36 | 1 1/2 | 1 3/4 | 5 1/2 |

| 6 to 36 | 2 | 1 1/2 | 5 1/2 |

| 6 to 36 | 3 | 1 21/32 | 7 |

| 6 to 36 | 4 | 2 1/32 | 8 3/4 |

| 10 to 36 | 6 | 2 11/16 | 13 |

| 12 to 36 | 8 | 3 | 15 |

| 16 to 36 | 10 | 3 1/8 | 18 1/2 |

| 16 to 36 | 12 | 3 5/16 | 20 1/2 |

| 20 to 36 | 14 | 3 5/8 | 24 |

| 24 to 36 | 16 | 3 3/4 | 28 |

| 24 to 36 | 18 | 4 5/8 | 31 |

| 24 to 36 | 20 | 5 1/8 | 33 |

| 30 to 36 | 24 | 5 5/8 | 38 |

Export Office: 21Floor, No.5 Nanhai Zhi Road,Qingdao, Shandong ,China

Work Shop: Beian Industrial zone, Qingdao,Shandong,China

+86 532 88550859

Joe

© 2020 Qingdao Fluido Industrial Co.,Ltd. All Rights Reserved. Qingdao fluido valve