Export Office: 21Floor, No.5 Nanhai Zhi Road,Qingdao, Shandong ,China

Work Shop: Beian Industrial zone, Qingdao,Shandong,China

+86 532 88550859

Joe

Inquiry now

Size: 1/8"-4"

Pressure:

Socket weld: 3000LB 6000LB 9000LB

Connection: Socket Welding

Standard: ANSI B16.11,EN10241, BS3799,JIS B2316,MSS SP-83,MSS SP-79;

Material: Stainless steel, Carbon steel

Socket Weld Coupling

A socket welding coupling is a type of high-pressure pipe fitting used to join two pipes together. It is a small device designed to connect two pipes of the same size and material by welding.

The socket welding coupling consists of one end socket and the other end ordinary. The socket end is to fit into the end of the pipe, while the ordinary end is used to connect to another pipe. The coupling is welded to the pipe using a socket welding technique, which involves heating the pipe and connecting it to a specific temperature, and then welding them together.

One of the main advantages of using socket-welded couplings is that it provide a strong and leak-proof connection between pipes. The welding process produces a tight seal that prevents leakage of any fluid or gas. This makes socket-welded joints ideal for high pressure and high-temperature applications where safe connections are necessary. Socket welding couplings are commonly used in industries such as oil and gas, chemical processing, and power generation.

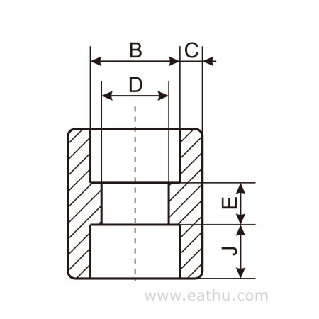

There are full couplings and half couplings socket weld type. On this page, you can find the socket weld full coupling dimensions and drawings.

Socket Weld Coupling Dimensions

| DN | Nom. | Socket | Bore Dia.Of Fitting | Socket Wall Thickness(2) | Laying Lengths | Depth of | End Wall Thickness | ||||||||||

| Pipe | Bore | D | C | Coupling | Half | Socket | Min. | ||||||||||

| Size | Dia. | Class Designation | E | Coupling | Min. | K | |||||||||||

| B | Class Designation | 3000 | 6000 | 9000 | F | J | Class Designation | ||||||||||

| 3000 | 6000 | 9000 | Ave. | Min. | Ave. | Min. | Ave. | Min. | 3000 | 6000 | 9000 | ||||||

| 6 | 1/8" | 10.8 | 6.9 | 4 | --- | 3.18 | 3.18 | 3.96 | 3.43 | --- | --- | 6.5 | 16 | 9.5 | 4.8 | 6.4 | --- |

| 8 | 1/4" | 14.2 | 9.3 | 6.4 | --- | 3.78 | 3.3 | 4.6 | 4.01 | --- | --- | 6.5 | 16 | 9.5 | 4.8 | 6.4 | --- |

| 10 | 3/8" | 17.6 | 12.6 | 9.2 | --- | 4.01 | 3.5 | 5.03 | 4.37 | --- | --- | 6.5 | 17.5 | 9.5 | 4.8 | 6.4 | --- |

| 15 | 1/2" | 21.8 | 15.8 | 11.8 | 6.4 | 4.67 | 4.09 | 5.97 | 5.18 | 9.35 | 8.18 | 9.5 | 22.5 | 9.5 | 6.4 | 7.9 | 11.2 |

| 20 | 3/4" | 27.2 | 21 | 15.6 | 11.1 | 4.9 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 | 9.5 | 24 | 12.5 | 6.4 | 7.9 | 12.7 |

| 25 | 1" | 33.9 | 26.7 | 20.7 | 15.2 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 | 12.5 | 28.5 | 12.5 | 9.6 | 11.2 | 14.2 |

| 32 | 1-1/4" | 42.7 | 35.1 | 29.5 | 22.8 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 | 12.5 | 30 | 12.5 | 9.6 | 11.2 | 14.2 |

| 40 | 1-1/2" | 48.8 | 40.9 | 34 | 28 | 6.35 | 5.54 | 8.92 | 7.8 | 12.7 | 11.12 | 12.5 | 32 | 12.5 | 11.2 | 12.7 | 15.7 |

| 50 | 2" | 61.2 | 52.5 | 42.9 | 38.2 | 6.93 | 6.04 | 10.92 | 9.5 | 13.84 | 12.12 | 19 | 41 | 16 | 12.7 | 15.7 | 19 |

| 65 | 2-1/2" | 73.9 | 62.7 | --- | --- | 8.76 | 7.67 | --- | --- | --- | --- | 19 | 43 | 16 | 15.7 | 19 | --- |

| 80 | 3" | 89.8 | 78 | --- | --- | 9.52 | 8.3 | --- | --- | --- | --- | 19 | 44.5 | 16 | 19 | 22.4 | --- |

| 100 | 4" | 115.2 | 102.3 | --- | --- | 10.69 | 9.35 | --- | --- | --- | --- | 19 | 48 | 19 | 22.4 | 28.4 | --- |

Export Office: 21Floor, No.5 Nanhai Zhi Road,Qingdao, Shandong ,China

Work Shop: Beian Industrial zone, Qingdao,Shandong,China

+86 532 88550859

Joe

© 2020 Qingdao Fluido Industrial Co.,Ltd. All Rights Reserved. Qingdao fluido valve