Export Office: 21Floor, No.5 Nanhai Zhi Road,Qingdao, Shandong ,China

Work Shop: Beian Industrial zone, Qingdao,Shandong,China

+86 532 88550858

Martin

Inquiry now

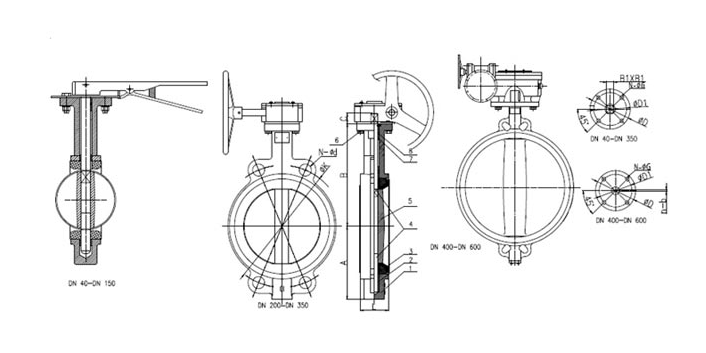

SIZE: 1 1/2"-24"

STANDARD:

Valve Design: BS EN593/BS5155/API609/DIN3354

Face to Face: ISO 5752-20/BS EN558-20/API609

Flange Drilling: ASME B16.1 Class125/ASME B16.5 CL150/ASME B16.47 CL150/ DIN 2501 PN10-16/EN1092 PN10-16/JIS10K

Hydraulic Test: EN12266-1/API 598/ISO5208/JIS B2003

Shell Test Pressure: 24 bar/15 bar

Sealing Test Pressure: 17.6 bar/11 bar

ACTUATOR

Handle Lever, Worm Gear, Pneumatic Actuator,Chain Operator

PRESSURE

Class 125/150, PN 10/16/25, 5K/10K/16K

Material List

Body Material:Cast Steel(WCB)Ductile Iron(GGG40/50)Gray Iron(GG25)

Disc Material:Ductile Iron Carbon SteelStainless Steel Aluminum Bronze

Stem Material:Stainless Steel

Seat Material:EPDM, NBR, PTFE, Metal

Wafer Type Butterfly Valve Specification

| SIZE | A | B | C | L | DIN PN 10 | DIN PN 16 | ANSI 150LB | JIS 10K | ISO 5211 | Top | B1XB1 | nb | |||||||

| mm | in | øK | N-ød | øK | N-ød | øK | N-ød | øK | N-ød | øD | øD1 | N-øG | Flange | ||||||

| 40 | 1½" | 67 | 141 | 32 | 33 | 110 | 4-ø18 | 110 | 4-ø18 | 98.5 | 4-ø16 | 105 | 4-ø19 | 65 | 50 | 4-ø8 | F05 | 9X9 | |

| 50 | 2" | 67 | 141 | 32 | 43 | 125 | 4-ø18 | 125 | 4-ø18 | 120.6 | 4-ø19 | 120 | 4-ø19 | 65 | 50 | 4-ø8 | F05 | 9X9 | |

| 65 | 2½" | 75 | 151 | 32 | 46 | 145 | 4-ø18 | 145 | 4-ø18 | 139.7 | 4-ø19 | 140 | 4-ø19 | 65 | 50 | 4-ø8 | F05 | 9X9 | |

| 80 | 3" | 95 | 160 | 32 | 46 | 160 | 8-ø18 | 160 | 8-ø18 | 152.4 | 4-ø19 | 150 | 8-ø19 | 65 | 50 | 4-ø8 | F05 | 9X9 | |

| 100 | 4" | 111 | 180 | 32 | 52 | 180 | 8-ø18 | 180 | 8-ø18 | 190.5 | 8-ø19 | 175 | 8-ø19 | 90 | 70 | 4-ø10 | F07 | 11X11 | |

| 125 | 5" | 129 | 193 | 32 | 56 | 210 | 8-ø18 | 210 | 8-ø18 | 215.9 | 8-ø22.4 | 210 | 8-ø23 | 90 | 70 | 4-ø10 | F07 | 14X14 | |

| 150 | 6" | 142 | 207 | 32 | 56 | 240 | 8-ø22 | 240 | 8-ø22 | 241.3 | 8-ø22.4 | 240 | 8-ø23 | 90 | 70 | 4-ø10 | F07 | 14X14 | |

| 200 | 8" | 170 | 240 | 45 | 60 | 295 | 8-ø22 | 295 | 12-ø22 | 298.4 | 8-ø22.4 | 290 | 12-ø23 | 125 | 102 | 4-ø12 | F10 | 17X17 | |

| 250 | 10" | 206 | 270 | 45 | 68 | 350 | 12-ø22 | 355 | 12-ø22 | 361.9 | 12-ø25.4 | 355 | 12-ø25 | 125 | 102 | 4-ø12 | F10 | 22X22 | |

| 300 | 12" | 238 | 316 | 45 | 78 | 400 | 12-ø22 | 410 | 12-ø26 | 431.8 | 12-ø25.4 | 400 | 16-ø25 | 125 | 102 | 4-ø12 | F10 | 22X22 | |

| 350 | 14" | 267 | 368 | 45 | 78 | 460 | 16-ø22 | 470 | 16-ø26 | 476.2 | 12-ø28.4 | 445 | 16-ø25 | 125 | 102 | 4-ø12 | F10 | 22X22 | |

| 400 | 16" | 298 | 400 | 51 | 86 | 515 | 12-ø26 | 525 | 16-ø30 | 539.7 | 16-ø28.4 | 510 | 16-ø27 | 175 | 140 | 4-ø18 | F14 | 1--10 | |

| 450 | 18" | 318 | 422 | 51 | 105 | 565 | 20-ø26 | 585 | 20-ø30 | 577.8 | 16-ø31.8 | 565 | 20-ø27 | 175 | 140 | 4-ø18 | F14 | 1--10 | |

| 500 | 20" | 349 | 479 | 57 | 130 | 620 | 20-ø26 | 650 | 20-ø33 | 635 | 20-ø31.8 | 620 | 20-ø27 | 175 | 140 | 4-ø18 | F14 | 1--12 | |

| 600 | 24" | 410 | 562 | 70 | 152 | 725 | 20-ø30 | 770 | 20-ø36 | 749.3 | 20-ø35.1 | 730 | 24-ø33 | 210 | 165 | 4-ø22 | F16 | 1--16 | |

Export Office: 21Floor, No.5 Nanhai Zhi Road,Qingdao, Shandong ,China

Work Shop: Beian Industrial zone, Qingdao,Shandong,China

+86 532 88550858

Martin

© 2020 Qingdao Fluido Industrial Co.,Ltd. All Rights Reserved. Qingdao fluido valve